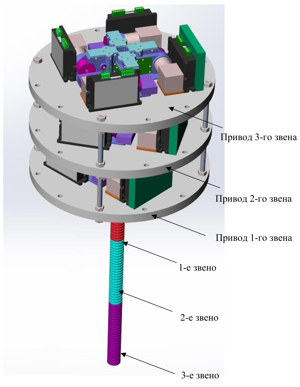

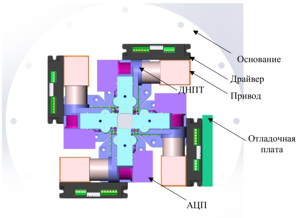

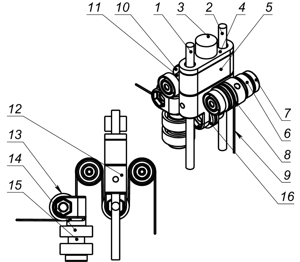

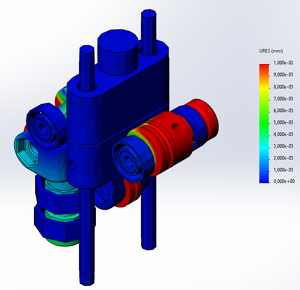

In modern industrial robotics, manipulators play a key role in ensuring uninterrupted production and automation, ensuring the required characteristics when working with movable objects. They make it possible to replace a person in monotonous operations, speed up the production process and avoid the use of additional lifting devices. Unlike traditional manipulators, continuous manipulators, with their unique capabilities, have unresolved control problems. One of them is to control the shape of the links of the continuous manipulator, as it ultimately determines its operating point. In this paper, we consider a continuous manipulator consisting of links based on rigid elements with a spherical surface, the rolling of which relative to each other determines the conical shape of the links. The rolling of the elements is carried out by means of drives by changing the lengths of the cables passing through them. For the correct (controlled) operation of the manipulator, it is necessary to control the movement of cables while simultaneously controlling their tension. In addition, to maintain the integrity of the links, the control must be synchronous for all cable drives. The main purpose of the presented work is to develop a draft design of a smart drive for atypical manipulators. At the first stage of the work, the results of which are presented in this article, a design study of the drive was carried out, for which the following three tasks were solved: designing a drive module based on a stepper motor with a cable tension and displacement sensor; developing an information system architecture; designing the internal structure of a programmable logic integrated circuit (FPGA). The circuit developed at the first (design) stage of creating the sketch design of the smart drive was loaded into the internal flash memory of the FPGA.

smart drive,

atypical manipulators,

cable tension and displacement sensor,

FPGAs,

stepper motors,

cable-driven control

Traditional manipulators have a limited number of degrees of freedom (currently, a significant proportion of industrial robots are manufactured with 5 or 6 degrees of freedom), which is ideal for structured environments, but leads to difficulties in using robots in poorly organized (non-deterministic) conditions, such as working in cluttered environments or when examining complex cavities of machines and mechanisms.. Manipulators with excessive degrees of freedom, which include snake-like manipulators based on a large number of modules, as well as continuous manipulators, can cope well with manipulative tasks in such conditions.

Unlike traditional manipulators, continuous manipulators have problems synthesizing the control system. One of the main problems is to control the shape of the links of the continuous manipulator, as it determines its operating point.

The aim of the work is to solve the problem of synthesizing an adaptive and multiconnected control system for continuous manipulators by developing a smart drive architecture with distributed data processing at the FPGA level and experimentally analyzing its effectiveness.

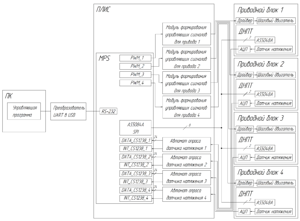

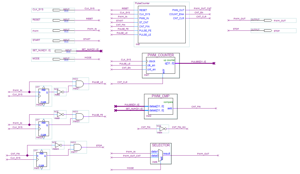

Methods. For the proper functioning of the manipulator, it is necessary to control the movement of the cables while simultaneously controlling their tension. In addition, to maintain the integrity of the links, the control must be synchronous for all cable drives. At the first stage of this development, the results of which are presented in this article, the design part of the work was carried out, for which the following three tasks were solved: designing a drive module based on a stepper motor with a tension sensor and cable displacement; developing an information system architecture; designing the internal structure of a programmable logic integrated circuit.

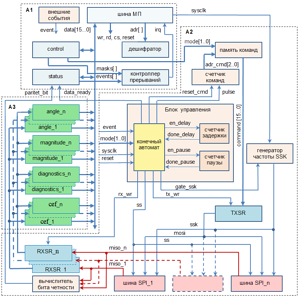

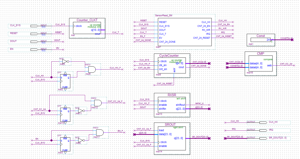

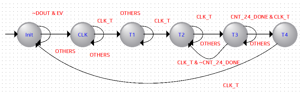

Results. At the first (design) stage, a draft design of a smart drive was synthesized, which allows simultaneously, in real time, to realize the movement of cables with control of the current tension. The resulting architecture was transformed into an image of a digital circuit (a digital twin of the drive) and loaded into the internal flash memory of the FPGA, which allows implementing the required control algorithms with synchronous control of the required parameters of all four actuators of the drive of this link of the manipulator.

Conclusions. The results show that the synthesized microprocessor system, which includes PWM signal generators for controlling drives, an AS5048A encoder polling component, data reception devices and an interrupt signal, make it possible to implement control signal generation modules for drives and strain gauge polling machines in real time. The use of FPGAs makes it easy to scale the resulting solution without reducing the overall system performance and significantly reduces the load on the top-level computer.