Gindullin I.I.

Statistical analysis of ESP defects detected during the robotization of control operations. Multiphase Systems. 19 (2024) 2. 79–85 (in Russian).

Statistical analysis of ESP defects detected during the robotization of control operations

I.I. Gindullin

Ufa State Petroleum Technological University, Ufa, Russia

Abstract

This article presents the prospects for using statistical analysis of defects in parts of electric centrifugal pumps (ECP) installations, which are

detected during cleaning, evaluation and flaw detection operations in a specialized robotic autonomous diagnostic module. A comprehensive

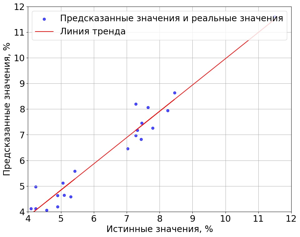

statistical analysis was carried out using methods of descriptive statistics, regression analysis, time series analysis and multidimensional

methods based on a representative database of ESP failures. The analysis of the regression analysis results revealed a significant influence

of temperature and pressure on the probability of defects in the ESP parts. Using the obtained result and data on operating modes, a

prototype of an expert-advising system has been implemented that generates recommendations for optimizing cleaning, evaluation and flaw

detection modes, indicating the most likely types of defects. The implementation of the proposed recommendations ensures a reduction

in time and cost costs for preparatory operations, weight and dimensional control, increased accuracy of flaw detection and, as a result,

increased reliability of the operation of the ESP, reduced operating costs of oil and gas producing enterprises. The conducted research

demonstrates a high potential for the application of modern statistical methods for solving practical problems in the oil and gas industry.

Keywordselectrical submersible pump units,

component defects,

statistical analysis,

regression analysis,

defectoscopy,

oil and gas industry

Article outline

Oil production is one of the key sectors of the Russian economy. The most common production technology used in 67% of oil wells is operation using electric centrifugal pumps (ECPS). At the same time, ESP failures are the main source of unplanned well downtime, which leads to significant economic losses. With an average duration of well operation of 30 years and an average maintenance period of 1.5 years, about 20 sets of pumps per well are required for uninterrupted operation. Often, failed ESPs are subject to restoration and reuse after repair, diagnosis and replacement of failed components. However, the repair processes involve the need to transport the ESP to specialized repair bases remote from the production sites. In large fields with a large number of wells (tens and hundreds), it is economically feasible to organize the repair of ESPs directly at the field to reduce downtime. This requires the creation of systems for the rational storage of parts and assemblies for their subsequent restoration and reuse.

Thus, the development of effective solutions for the storage and prompt delivery of ESP parts for field repairs becomes an urgent task. Its solution will significantly increase the productivity of oil production and reduce the material costs associated with well downtime. The object of the study is the subsystem of automated storage of ESP units, implemented as part of a robotic complex for flaw detection, sorting, and storage of parts. In connection with the above, in order to intensify the process, increase efficiency, quality and objectification of cleaning, flushing and flaw detection operations of ESP parts, it is proposed not only to automate control operations through the use of an industrial robot, but also to develop a methodology for applying statistical methods for analyzing received and input information. The use of a statistical apparatus will optimize the cleaning and washing modes of parts entering the complex, as well as implement flexible, adaptive algorithms for detecting and classifying defects with a high degree of accuracy. The correct use of statistical methods will significantly reduce the time spent on preparatory operations when parts are submitted for inspection and improve the quality of their flaw detection, ensuring rapid detection of defective elements. This, in turn, will prevent equipment failures, minimize the costs associated with repairs and downtime, as well as increase the level of industrial safety of technological processes.

The main purpose of this study is to conduct a statistical analysis of defects in ESP parts in order to develop recommendations for intensifying and improving the efficiency of their cleaning, flushing, followed by flaw detection. To achieve this goal, it is assumed that the following set of interrelated tasks will be solved:

- To analyze the existing methods of statistical investigation of defects in application to objects of the oil and gas industry in order to determine the most promising approaches.

- To form a representative database of defects in ESP parts, including information on the types, localization, characteristics of defects, as well as operating conditions of the equipment.

- Make an informed choice of statistical methods and software tools for analyzing the generated database.

- To conduct a statistical study of defects in ESP parts using methods of descriptive statistics, cluster analysis, multidimensional scaling and other relevant methods.

- To identify patterns of occurrence and interrelation of various types of defects based on the results of the statistical analysis.

- Develop recommendations for optimizing cleaning and washing modes of parts, taking into account the identified patterns to improve the productivity of these operations.

- To propose an improved flaw detection system for ESP parts using methods of automatic defect classification based on statistical analysis to improve the speed and quality of control.

- To assess the potential economic effects of the implementation of the developed recommendations for the intensification of the processes of preparation and control of ESP parts.

Based on the results of the analysis of the applicability of statistical methods, a group of methods was selected depending on the tasks to be solved, a statistical analysis of the causes of ESP failures and characteristic damage to parts in the conditions of a specific oil field was performed.

Software for control the uploading module has been created, including software modules, algorithms, user interfaces and allowing to reduce loading/unloading, to provide full information support of the technological process. Model and computer studies of the developed module were carried out, the analysis of the results obtained, which confirmed the required indicators, was performed.

References

- Эконометрика: учебник для вузов / И.И. Елисеева [и др.]; под редакцией И.И. Елисеевой. Москва: Издательство Юрайт, 2024. 449 с.

[Econometrics: textbook for universities] Ekonometrika: uchebnik dlya vuzov (ed. I.I. Eliseeva). Moscow: Izdatel’stvo Yurajt, 2024. P. 449 (in Russian).

https://urait.ru/bcode/535449

- Орлов А.И. Прикладная статистика. М.: Экзамен, 2006. 671 с.

Orlov A.I. [Applied Statistics] Prikladnaya statistika. Moscow: Ekzamen, 2006. P. 671 (in Russian).

- Ивановский В.Н., Пекин С.С., Сабиров А.А. Установки погружных центробежных насосов для добычи нефти. М.: ГУП Изд-во «Нефть и газ» РГУ

нефти и газа им. И.М. Губкина, 2002. 256 с.

Ivanovskij V.N., Pekin S.S., Sabirov A.A. [Installations of submersible centrifugal pumps for oil production] Ustanovki pogruzhnyh centrobezhnyh nasosov

dlya dobychi nefti. Moscow: GUP Izd-vo «Neft’ i gaz» RGU nefti i gaza im. I.M. Gubkina, 2002. P. 256 (in Russian).

- Ляпков П.Д. Подбор установки погружного центробежного насоса к скважине. М.: МИНГ, 1987. 71 с.

Lyapkov P.D. [Selection of installation of a submersible centrifugal pump for a well] Podbor ustanovki pogruzhnogo centrobezhnogo nasosa k skvazhine.

Moscow: MING, 1987. P. 71 (in Russian).

- Мищенко И.Т. Скважинная добыча нефти: Учебное пособие для вузов. М.: ФГУП Изд-во «Нефть и газ» РГУ нефти и газа им. И.М. Губкина, 2003. 816 с.

Mishchenko I.T. [Well oil production: A textbook for universities] Skvazhinnaya dobycha nefti: Uchebnoe posobie dlya vuzov. Moscow: FGUP Izd-vo «Neft’ i

gaz» RGU nefti i gaza im. I.M. Gubkina, 2003. P. 816 (in Russian).

- Ивановский В.Н., Дарищев В.И., Сабиров А.А. и др. Оборудование для добычи нефти и газа: В 2 т. М.: ВНИИОЭНГ, 2001. Т. 1. 304 с.

Ivanovskij V.N., Darishchev V.I., Sabirov A.A. et al.[Equipment for oil and gas production] Oborudovanie dlya dobychi nefti i gaza. M.: VNIIOENG, 2001. Vol. 1.

P. 304 (in Russian).

- Мухаметшин В.Ш. Моделирование процесса нефтеизвлечения с использованием опыта разработки месторождений, находящихся длительное

время в эксплуатации // Нефтегазовое дело. 2011. Т. 9, № 4. С. 47–50.

Mukhametshin V.Sh. Model for ecast of the oil recovery process using development experience of old-run fields. Petroleum engineering. 2011. Vol. 9,

no. 4. Pp. 47–50 (in Russian).

EDN: PANEIJ

- Галлямов М.Н., Рахимкулов Р.Ш. Повышение эффективности эксплуатации нефтяных скважин на поздней стадии разработки месторождений.

Москва: Недра, 1978. 207 с.

Gallyamov M.N., Rahimkulov R.Sh. [Increasing the efficiency of oil well operation at a late stage of field development] Povyshenie effektivnosti ekspluatacii

neftyanyh skvazhin na pozdnej stadii razrabotki mestorozhdenij. Moscow: Nedra, 1978. P. 207 (in Russian).

- Серебренников А.В., Петрикевич П.А., Тороп О.В., Фролов В.В. Эксплуатация механизированного фонда скважин в осложненных условиях //

Деловой журнал Neftegaz.RU. 2017. № 7(67). С. 86–97.

Serebrennikov A.V., Petrikevich P.A., Torop O.V., Frolov V.V. [Operation of mechanized well stock in difficult conditions] Ekspluataciya mekhanizirovannogo

fonda skvazhin v oslozhnennyh usloviyah. Delovoj zhurnal Neftegaz.RU. 2017. N0. 7(67). Pp. 86–97 (in Russian).

EDN: ZRZUHP

- Ибрагимов Н.Г., Хафизов А.Р., Шайдаков В.В. Осложнения в нефтедобыче. Уфа: Монография, 2003. 302 с.

Ibragimov N.G., Hafizov A.R., Shajdakov V.V. [Complications in oil production] Oslozhneniya v neftedobyche. Ufa: Monografiya, 2003. P. 302 (in Russian).

- Антониади Д.Г., Гарушев А.Р., Ишханов В.Г. Настольная книга по термическим методам добычи нефти. Краснодар: Советская Кубань, 2000. 461 с.

Antoniadi D.G., Garushev A.R., Ishkhanov V.G. [Handbook on thermal methods of oil production] Nastol’naya kniga po termicheskim metodam dobychi nefti.

Krasnodar: Sovetskaya Kuban’, 2000. P. 461 (in Russian).

- Соловьев И.Г., Константинов И.В., Говорков Д.А. Оптимизация параметров обустройства и режима эксплуатации скважины с ЭЦН в условиях

осложнений // Автоматизация, телемеханизация и связь в нефтяной промышленности. 2019. № 9(554). С. 28–35.

Solovyev I.G., Konstantinov I.V., Govorkov D.A. Optimization of equipment parameters and a well operational mode with esp under conditions of

complications. Automation, telemechanization and communication in oil industry. 2019. No. 9(554). Pp. 28–35 (in Russian).

DOI: 10.33285/0132-2222-2019-9(554)-28-35

- Сабиров А.А., Деговцов А.В., Кузнецов И.В., Алиев Ш.А., Мазеин И.И., Меркушев С.В., Красноборов Д.Н. Прогнозирование наработки на отказ,

выбор исполнения и оптимизация закупок установок электроцентробежных насосов для осложненного фонда скважин // Территория Нефтегаз.

2019. № 7–8. С. 44–48.

Sabirov A.A., Degovtsov A.V., Kuznetsov I.V., Aliev Sh.A., Mazein I.I., Merkushev S.V., Krasnoborov D.N. Forecasting the operating time to failure, selection

of design and optimization of procurement of electric centrifugal pump installations for complicated wells stock. Territorija neftegaz. 2019. No. 7–8.

Pp. 44–48 (in Russian).

EDN: IMAHPU

- Бахтизин Р.Н., Уразаков К.Р., Латыпов Б.М., Ишмухаметов Б.Х. Утечки жидкости в штанговом насосе с регулируемым ходом плунжера //

Нефтегазовое дело. 2016. Т. 14, № 4. С. 33–39.

Bachtizin R.N., Urazakov K.R., Latypov B.M., Ishmuchametov B.H. Fluid leakage in a sucker-rod pump with regular micro-relief at surface of the plunger.

Petroleum engineering. 2016. Vol. 14, no. 4. Pp. 33–39 (in Russian).

EDN: YNBDMV

- Шангараева Л.А., Максютин А.В., Султанова Д.А. Способы предотвращения солеотложения при разработке и эксплуатации залежей нефти //

Современные проблемы науки и образования. 2015. № 1-1. C. 336.

Shangaraeva L.A., Maksyutin A.V., Sultanova D.A. Methods to prevent scale during the development and exploitation of oil fields. Sovremennyye

problemy nauki i obrazovaniya. 2015. No. 1-1. P. 336 (in Russian).

EDN: VIDYCV