Robotics is an interdisciplinary scientific direction, therefore, when solving a number of problems, it becomes necessary to conduct research that is typical for other areas of science. So, when synthesizing new types of equipment in the „Robotics and Control in Technical Systems” laboratory, more accurate characteristics of individual components and assemblies were required, which ultimately led to a whole cycle of work on microfluidics. Of particular interest in the work performed is the development of new microdevices, since this involves the construction of a single complex of new mathematical and computer models that link hydrodynamics, elasticity theory, heat transfer process, parametric optimization and control theory. The first models were obtained that describe the movement of a piston fixed by an elastic spring in a pipe, taking into account the influence of dry viscous types of friction. By the method of factorial computational experiment, analytical dependencies were obtained for the main part of the fuel dosing unit — servo piston. Next, mathematical and computer models were built to analyze the fluid flow through a channel with variable geometry. Based on the simulation results, the design of a new micromechanical device — a piezoelectric micropump consisting of an elastic tube and annular piezoelements located on it, the sequential oscillation of which creates a non-zero average fluid flow, was refined. In the course of the adaptation of the model, an effective design of the device for smoothing fluid flow pulsations was obtained. These devices were developed and calculated for use in the liquid cooling system of capillary microgripper. A parametric analysis of the process of cooling the hot side of the Peltier element of the microgripper was carried out with a change in the following gripper parameters: the size and shape of the radiator, the coolant flow rate and the heat transfer coefficient. The results of the analysis of temperature fluctuations of the radiator under unsteady fluid flow confirmed the expected dependences of the cooling efficiency on the chosen geometry of the radiator and low-frequency fluid flow fluctuations.

microfluidics,

microrobotics,

hydraulic resistance,

dynamically variable channel geometry,

piezoelectric micropump,

capillary microgripper,

fluid cooling system

Robotics is an interdisciplinary scientific direction, therefore, when solving a number of problems, it becomes necessary to conduct research that is typical for other areas of science. So, when synthesizing new types of equipment in the “Robotics and Control in Technical Systems” laboratory, more accurate characteristics of individual components and assemblies were required, which ultimately led to a whole cycle of work on microfluidics.

Of particular interest in the work performed is the development of new microdevices, since this involves the construction of a single complex of new mathematical and computer models that link hydrodynamics, elasticity theory, heat transfer process, parametric optimization and control theory.

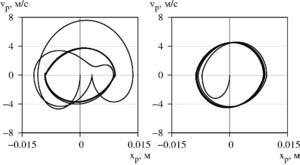

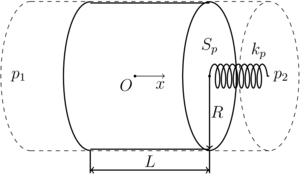

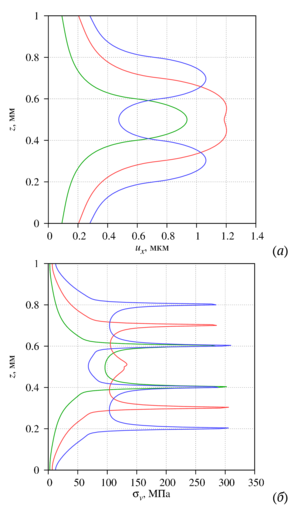

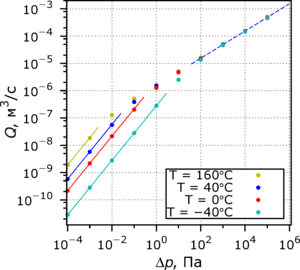

The first models were obtained that describe the movement of a piston fixed by an elastic spring in a pipe, taking into account the influence of dry and viscous types of friction. The combined effect of the spring stiffness and dry friction leads to the fact that the equilibrium point is determined by the presence of the spring stiffness, and the oscillation period is determined by the presence of the dry friction force (oscillations occur at the frequency of the pressure drop, and not at the natural frequency). With an increase in both the spring stiffness and the dry friction force, the amplitude of the piston oscillations decreases. For small friction forces (both dry and viscous), the transition to a periodic mode of motion occurs in a large number of cycles. In a system with a spring, the effect of viscous friction is significant. At large pressure drops, the curvature of the pipe can be neglected and the problem can be reduced to an unsteady parallel flow in a flat capillary. Mathematical and computer models of the servopiston are constructed. The factors of the computational experiment and the response functions are chosen. An approximation of the response functions in the form of a polynomial with linear, pair and quadratic contributions of the factors is proposed. The essential factors of the piston dynamics and their interaction and the approximation error are determined. The temperature dependences of the parameters have been established, which makes it possible to carry out an adequate simulation of the operation of the element, taking into account dynamic changes in this element during operation. A method for combining individual elements of a computing stand into a system is shown. A method for increasing the strength of the piston surface to cavitation effects is presented. Calculations have shown that with special treatment, the piston surface will become more resistant to erosion damage; deformations are localized near the area to which the force is applied, at a distance of about two bubble diameters; cavitation destruction of the material is related to the yield threshold and grain size, does not depend on the Young's modulus and is inversely proportional to the Poisson's ratio; the simultaneous collapse of two bubbles at a distance of the order of one or two bubble sizes increases the maximum pressure on the surface and, consequently, increases the probability of irreversible deformation of the surface.

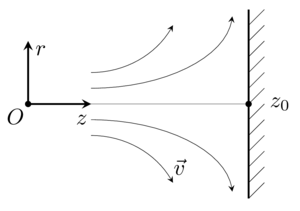

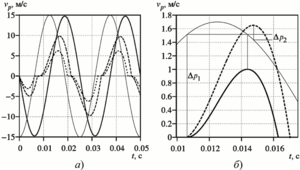

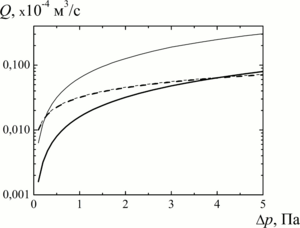

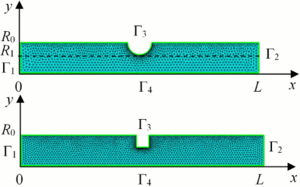

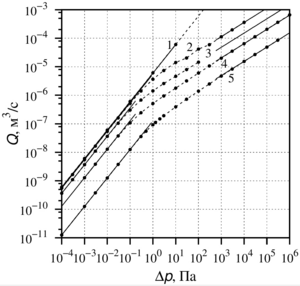

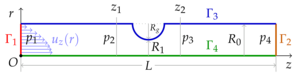

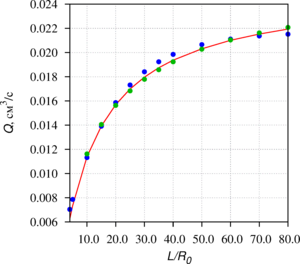

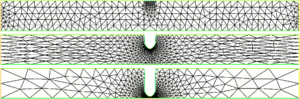

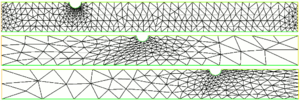

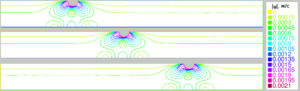

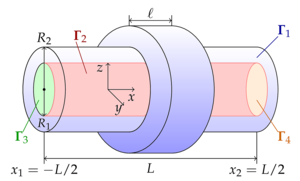

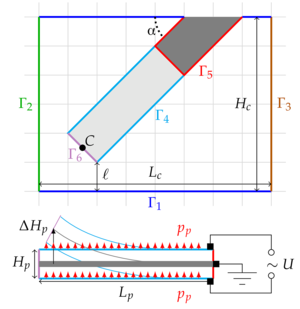

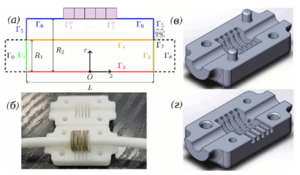

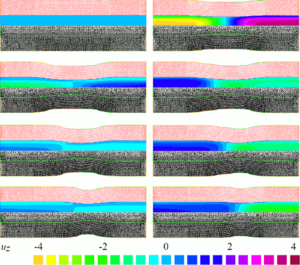

Next, mathematical and computer models were built to analyze the fluid flow through a channel with variable geometry. Simulation of dynamic geometry change opens up great opportunities in the development of new technical devices. For example, the longitudinal movement of the hydraulic resistance can be used to create a flow in a channel with a constant pressure, and the transverse compression can be used to control the fluid flow in a channel with a non-zero pressure drop. Based on the simulation results, the design of a new micromechanical device was refined - a piezoelectric micropump consisting of an elastic tube and annular piezoelements located on it, the sequential oscillation of which creates a non-zero average fluid flow. In the course of the adaptation of the model, an effective design of the device for smoothing fluid flow pulsations was obtained.

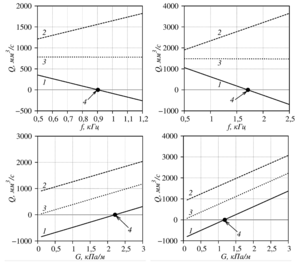

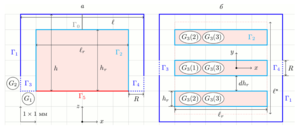

These devices were developed and calculated for use in the fluid cooling system of capillary microgripper. A parametric analysis of the process of cooling the hot side of the Peltier element of the microgripper was carried out with a change in the following gripper parameters: the size and shape of the radiator, the coolant flow rate and the heat transfer coefficient.

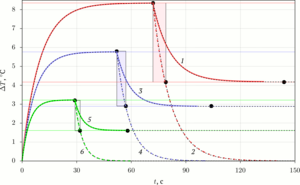

The results of the analysis of temperature fluctuations of the heatsink under unsteady fluid flow confirmed the expected dependences of the cooling efficiency on the chosen geometry of the heatsink and low-frequency fluid flow fluctuations. An analysis was made of switching the cooling system from one operating mode to another. It was found that the time for establishing the operating mode coincides with the duration of switching to another mode of operation and does not depend on the thermal power of the Peltier element, which made it possible to propose a mechanism for “fast” mode switching. Based on the results of a numerical calculation, one-parameter analytical approximations were constructed for the dependence of the heat sink temperature on time, as well as the duration of the “fast” switching.