Borisoglebskiy I.K., Metusova M.V., Mikhaylenko C.I.

The dependence of the Ranque–Hilsch effect on the cold outlet geometry.

Multiphase Systems. 13 (2018) 3. 52–58.

The dependence of the Ranque–Hilsch effect

on the cold outlet geometry

Borisoglebskiy I.K.∗,

Metusova M.V.∗, Mikhaylenko C.I.∗∗

∗Ufa State Aviation Technical University, Ufa

∗∗Mavlyutov Institute of Mechanics, UFRC RAS, Ufa

Abstract

The effect of such parameters of the cold outlet nozzle

of the counter flow vortex tube as the length and widening angle on temperature separation

is investigated. Mathematical model of gas dynamics is written with viscosity component.

Computational simulation is performed in the OpenFOAM package, using the sonicFoam solver.

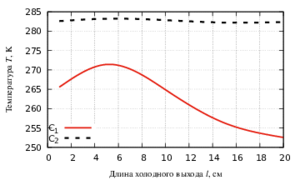

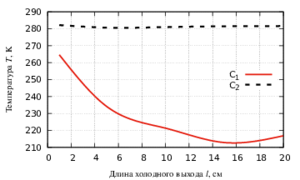

It is shown that the temperature of the exhaust air decreases along the cold exit nozzle.

The presence of the angle of widening of the nozzle affects the amount of cooling, but is

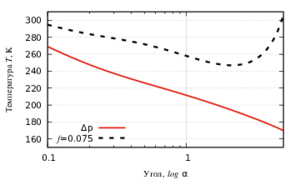

not the root cause of the effect. The nonmonotonic dependence of the temperature of the

exhaust gas on the length of the cold exit nozzle is demonstrated. When studying the effect

on the temperature of the widening angle of a cold-exit nozzle at a fixed length, it was

shown that at a fixed volume flow rate, a pronounced non-monotonic dependence is observed,

while at a constant pressure drop, there is no non-monotony down to the maximum considered

angle.

Keywordsmathematical modeling,

gas dynamics,

vortex tube,

Ranque–Hilsch effect,

OpenFOAM,

turbulence

Article outline

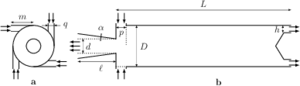

In the paper, the influence of the geometric parameters

of the cold outlet nozzle of a counter flow vortex tube on the result of the Ranque–Hilsch

effect is studied using a mathematical modeling. The investigated parameters are the length

and angle of widening of the channel. All other geometry parameters of a vortex tube remains

unchanged.

Computational experiments are calculated in an OpenFOAM environment. The sonicFoam solver

is used to simulate the sound waves with shock waves. Such flow regimes are realized in the

channel of the vortex tube.

The influence of turbulent pulsations on the result of the solution is smoothed as follows.

The measured value (temperature, pressure, speed) is averaged over time over the last few

calculated steps. Averaging over a certain cross section is also carried out, the values

of which are calculated using the surfaceCut utility. The behavior of temperature and

pressure at the cold outlet, as well as in the cross section of the transition from the

channel of the main pipe to the cold exit nozzle, is investigated. In addition, calculations

are performed under different boundary conditions at the inlet: constant volume flow rate

and constant pressure.

The following results were obtained. The geometrical parameters of the nozzle of the cold

exit of the vortex tube have a significant impact on the production of cold air. It is shown

that the condition of constant inlet pressure gives a better result compared with a fixed

volumetric flow rate. It is also shown that the main cooling of the exhaust air takes place

directly in the cold outlet nozzle, regardless of its geometry.

References

- Finko V.E. Cooling and condensation of a gas in

a vortex flow // Soviet Physics Technical Physics. 1983. V. 28(9). Pp. 1089–1093.

- Bruno T.J. Laboratory applications of the vortex tube //

Journal of Chemical Education. 1987. V. 64. Pp. 987–988.

(DOI: 10.1021/ed064p987)

- Baz A., Gilheany J., Kalvitas A. Feasibility of vortex tube assisted environmental

control of an unde rwater research habitat // Ocean Eng. 1988. V. 15(1). Pp. 33–54.

(DOI: 10.1016/0029-8018(88)90018-2)

- Riu K, Kim J, Choi IS. Experimental investigation on dust separation characteristics of

a vortex tube // Trans JSME Ser B: Therm Fluid Mech. 2004. V. 47(1). Pp. 29–36.

(DOI: 10.1299/jsmeb.47.29)

- Martin R.W., Zilm K.W. Variable temperature system using vortex tube cooling and

fiber optic temperat ure measurement for low temperature magic angle spinning NMR //

J. Magn. Reson. 2004. V. 168(2). Pp. 202–209.

(DOI: 10.1016/j.jmr.2004.03.002)

- Kumar A., Vivekanand, Subudhi S. Cooling and dehumidification using vortex tube //

Applied Thermal Engineering. 2017. Vol. 122. Pp. 181–193.

(DOI: 10.1016/j.applthermaleng.2017.05.015)

- Гуцол А.Ф. Эффект Ранка // Успехи физических наук. 1997. Т. 167, №6. С. 665–687.

(DOI: 10.1070/PU1997v040n06ABEH000248)

- Eiamsa-ard S., Promvonge P. Review of Ranque–Hilsch effects in vortex tubes //

Renewable and Sustainable Energy Reviews. 2008. V. 1. Pp. 1822–1842.

(DOI: 10.1016/j.rser.2007.03.006)

- Subudhi S., Mihir S. Review of Ranque–Hilsch vortex tube experiments using air //

Renewable and Sustainable Energy Reviews. 2015. Vol. 52. Pp. 172–178.

(DOI: 10.1016/j.rser.2015.07.103)

- Bo Zhang, Xiangji Guo, Zhuqiang Yang Analysis on the fluid flow in vortex tube with

vortex periodical oscillation characteristics // International Journal of Heat and Mass Transfer.

2016. V. 103. Pp. 1166–1175.

(DOI: 10.1016/j.ijheatmasstransfer.2016.08.063)

- Majidi D., Alighardashi Н., Farhadi F., Best vortex tube cascade for highest thermal

separation // International Journal of Refrigeration. 2017. V. 85. Pp. 282–291.

(DOI: 10.1016/j.ijrefrig.2017.10.006)

- Moraveji A.,Toghraie D. Computational fluid dynamics simulation of heat transfer and

fluid flow characteristics in a vortex tube by considering the various parameters //

Int.J. of Heat and Mass Transfer. 2017. V. 113. Pp. 432–443.

(DOI: 10.1016/j.ijheatmasstransfer.2017.05.095)

- Hamdan M.O., Al-Omari S.-A., Oweimer A.S. Experimental study of vortex tube energy

separation under different tube design // Experimental Thermal and Fluid Science.

2018. V. 91. Pp. 306–311.

(DOI: 10.1016/j.expthermflusci.2017.10.034)

- Thakare H.R., Monde A., Parekh A.D. Experimental, computational and optimization studies

of temperature separation and flow physics of vortex tube: A review // Renewable and Sustainable

Energy Reviews. 2015. V. 52. Pp. 1043–1071.

(DOI: 10.1016/j.rser.2015.07.198)

- Mohammadi S., Farhadi F.Experimental and numerical study of the gas–gas separation

efficiency in a Ranque–Hilsch vortex tube // Separation and Purification Technology.

2014. V. 138. Pp. 177–185.

(DOI: 10.1016/j.seppur.2014.10.022)

- Attalla M., Ahmed H., Ahmed M.S., El-Wafa A.A. An experimental study of nozzle number

on Ranque–Hilsch counter-flow vortex tube // Experimental Thermal and Fluid Science.

2017. V. 82. Pp. 381–389.

(DOI: 10.1016/j.expthermflusci.2016.11.034)

- Марьин Д.Ф., Михайленко К.И. Численное исследование механизма возникновения эффекта

Ранка--Хилша в канале вихревой трубы // Вестник Нижегородского университета

им. Н.И. Лобачевского. 2011. № 4–3. С. 977–-978.

- Марьин Д.Ф., Михайленко К.И., Хазиев Л.Х. Прямое численное моделирование эффекта ранка //

В сборнике: Параллельные вычислительные технологии (ПаВТ'2011) Труды международной научной

конференции. 2011. С. 539–547.

(URL: http://omega.sp.susu.ru/books/conference/PaVT2011/short/197.pdf)

- Михайленко К.И. Зависимость перераспределения температуры в вихревой трубе от геометрии

завихрителя // Труды Института механики им. Р.Р. Мавлютова Уфимского научного центра РАН.

2017. Т. 12, № 2. С. 174–179.

(DOI: 10.21662/uim2017.2.026)

- Михайленко К.И. К моделированию вихревой трубы: подготовка гексагональной сетки для

вычислительных экспериментов в среде OpenFOAM //

Труды Института механики им. Р.Р. Мавлютова УНЦ РАН. 2016. Т. 11, № 1. С. 112–118.

(DOI: 10.21662/uim2016.1.017)