Ronzhin R.P. , Mikhaylenko C.I.

On the dependence of a cold air production on the size of a hot air output area of the vortex tube.

Multiphase Systems. 13 (2018) 3. 29–35.

On the dependence of a cold air production on the size of

a hot air output area of the vortex tube

Ronzhin R.P.∗, Mikhaylenko C.I.∗∗

∗ Ufa State Aviation Technical University, Ufa

∗∗ Mavlutov Institute of Mechanics, UFRC RAS, Ufa

Abstract

A model of a counterflow vortex tube is presented to

investigate the dependence of the influence of hot exit area on the temperature separation.

Computational experiments were done for 37 models for different values of the area of

the hot exit ring. In a number of experiments, the pressure of the air supplied to the inlet

varies in order to take into account the possible effects of computational and model errors.

An anomalous result is obtained for the value of the hot exit area

∼30 cm2. Conclusions are drawn about the range of the most suitable

hot exit sizes for the considered configuration of the vortex tube.

Keywordsmathematical modeling,

gas dynamics,

vortex tube,

Ranque–Hilsch effect,

OpenFOAM,

turbulence

Article outline

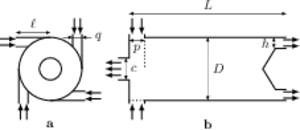

It is investigate the effect of one of the geometric parameters of the counterflow

vortex tube on the magnitude of the Rank-Hilsch effect. The parameter being tested is the hot output size, given by its area.

The other of the geometry of the vortex tube remains unchanged.

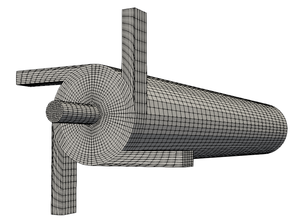

Computational experiments are conducted in the OpenFOAM environment. The sonicFoam solver is used for the simulation

of sonic flows with shock waves. Similar flow regimes are realized in the vortex tube channel.

To take into account the effect of turbulence on the result of the decision, the following steps have been taken.

Measured value (temperature or pressure) is averaged over time at the last few calculated steps.

Averaging is also performed over a certain cut, the values in which are calculated by the surfaceCut utility.

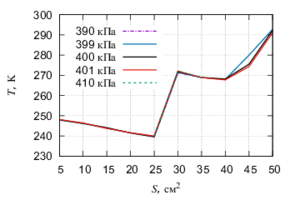

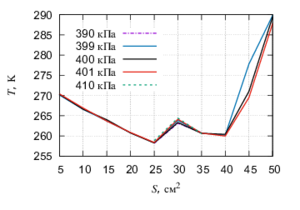

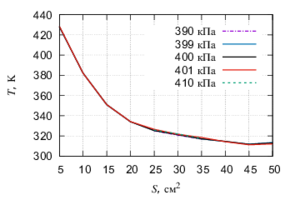

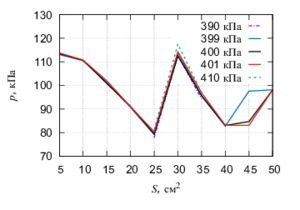

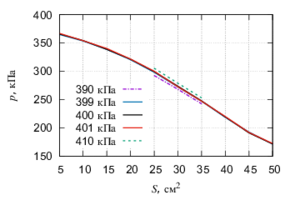

The behavior of temperature and pressure at cold and hot exits, as well as in the cross section of the transition

from the channel of the main pipe into the nozzle of the cold outlet is investigated.

In addition, the calculations were carried out for several pressure values at the inlet.

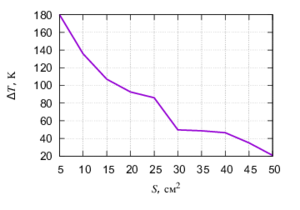

The following results were obtained during the work. The size of the hot outlet has a significant effect on magnitude

of the vortex effect. If we consider a vortex tube as a generator of cold and hot air at the same time, one can speak of

a range of values of the area of the hot section, at which the temperature separation is greatest. For the investigated

geometry, this range is S=20÷40 cm2. For the area of the section

S≈30 cm2, anomalous results are obtained at the cold exit.

References

- Ranque G.J. Experiments on expantion a vortex with

Simultaneous Exhaust of hot air and cold air (in French) // J. Phys. Radium. 1933. V. 4. Pp. 112–114.

- Hilsch R. The use of the expansion of gases in a centrifugal

field as cooling process // Review of Sientific Instruments. 1947. V. 18. Pp. 108–113.

(DOI: 10.1063/1.1740893)

- Balmer, R. T., Pressure-Driven Ranque-Hilsch Temperature

Separation in Liquids // J. Fluids Eng. 1988. V. 110(2). Pp. 161–164.

(DOI: 10.1115/1.3243529)

- Гуцол А.Ф. Эффект Ранка // Успехи физических наук. 1997. Т. 167, No 6. С. 665–687.

(DOI: 10.3367/UFNr.0167.199706e.0665)

- Eiamsa-Ard S., Promvonge P. Review of Ranque-Hilsch effects

on vortex tubes // Renewable and Sustainable Energy Reviews. 2008. V. 1. Pp. 1822–1842.

(DOI: 10.1016/j.rser.2007.03.006)

- Subudhi S., Sen M. Review of Ranque–Hilsch vortex tube experiments using air // Renewable and Sustainable Energy

Reviews. 2015. V. 52. Pp. 172–178.

(DOI: 10.1016/j.rser.2015.07.103)

- Valipour M.S., Niazi N. Experimental modeling of a curved Ranque–Hilsch vortex tube refrigerator // International

Journal of Refrigeration. 2011. V. 34(4). Pp. 1109–1116.

(DOI: 10.1016/j.ijrefrig.2011.02.013)

- Xue Y., Arjomandi M., Kelso R. A critical review of temperature

separation in a vortex tube // Experimental Thermal and Fluid Science. 2010. V. 34(8). Pp. 1367–1374.

(DOI: 10.1016/j.expthermflusci.2010.06.010)

- Khait A., Noskov A., Alekhin V., Bianco V. Analysis of the local

entropy generation in a double-circuit vortex tube // Applied Thermal Engineering. 2018. V. 130. Pp. 1391–1403.

(DOI: 10.1016/j.applthermaleng.2017.11.136)

- Марьин Д.Ф., Михайленко К.И. Численное исследование механизма возникновения эффекта Ранка–Хилша в канале

вихревой трубы // Вестник Нижегородского университета им. Н.И. Лобачевского. 2011. No 4-3. С. 977–978.

- Марьин Д.Ф., Михайленко К.И., Хазиев Л.Х. Прямое численное моделирование эффекта ранка // В сборнике:

Параллельные вычислительные технологии (ПаВТ’2011) Труды международной научной конференции. 2011. С. 539–547.

(http://omega.sp.susu.ru/books/conference/PaVT2011/short/197.pdf)

- Михайленко К.И. Зависимость перераспределения температуры в вихревой трубе от геометрии завихрителя // Труды

Института механики им. Р.Р. Мавлютова Уфимского научного центра РАН. 2017. Т. 12, No 2. С. 174–179.

(DOI: 10.21662/uim2017.2.026)

- Михайленко К.И. К моделированию вихревой трубы: подготовка гексагональной сетки для вычислительных экспериментов

в среде OpenFOAM // Труды Института механики им. Р.Р. Мавлютова УНЦ РАН. 2016. Т. 11, No 1. С. 112–118.

(DOI: 10.21662/uim2016.1.017)

- Михайленко К.И., Валеева Ю.Р. Моделирование осаждения мелкодисперсной взвеси из воздуха при прохождении волн

давления // Вычислительные методы и программирование: новые вычислительные технологии. 2013. Т. 14, No 1. С. 328–333.

(http://num-meth.srcc.msu.ru/zhurnal/tom_2013/v14r136.html)